Revolutionize Metalwork With Cutting-Edge 3D CAD Technology: Unleash Creativity And Precision With Metalwork 3D CAD

The Magic of Metalwork 3D CAD: A Blogger’s Experience

Are you ready to dive into the fascinating world of metalwork 3D CAD? Buckle up, because I’m about to take you on a thrilling journey through the wonders of this innovative technology. As a passionate blogger, I’ve had the opportunity to explore various products, but metalwork 3D CAD has truly captured my attention. In this article, I’ll share my experiences, insights, and recommendations, making sure you’re equipped with all the necessary information about this incredible tool.

What is Metalwork 3D CAD?

Metalwork 3D CAD, also known as three-dimensional computer-aided design, is a revolutionary technology that enables designers and engineers to create intricate and precise metalwork models virtually. This powerful tool allows for the creation of complex designs with ease, making it an essential asset in various industries, including aerospace, automotive, jewelry, and architecture.

2 Picture Gallery: Revolutionize Metalwork With Cutting-Edge 3D CAD Technology: Unleash Creativity And Precision With Metalwork 3D CAD

Who Can Benefit from Metalwork 3D CAD?

The beauty of metalwork 3D CAD lies in its versatility. Whether you’re an experienced designer, a budding entrepreneur, or a hobbyist, this technology has something to offer. Design professionals can leverage its capabilities to bring their ideas to life, while businesses can streamline their manufacturing processes, reducing costs and improving efficiency. Even if you’re simply an enthusiast with a passion for creating, metalwork 3D CAD allows you to unleash your creativity without limitations.

When and Where Can Metalwork 3D CAD Be Used?

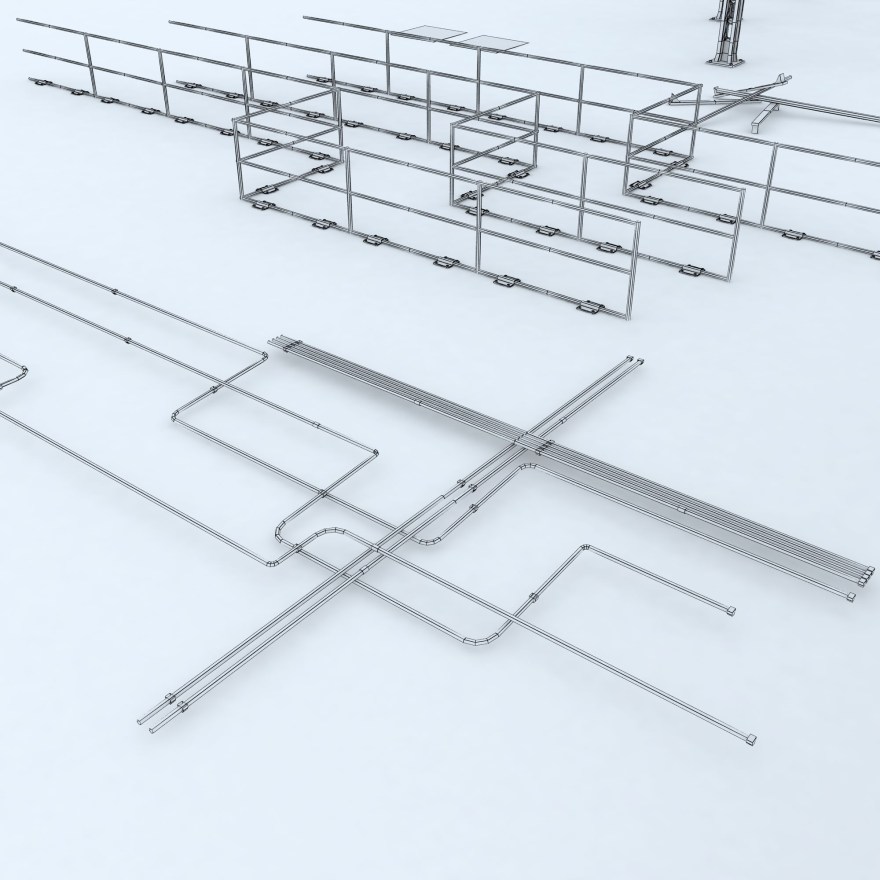

Image Source: free3d.com

Metalwork 3D CAD can be utilized at various stages of the design and manufacturing process. It serves as a powerful tool during the conceptualization phase, where designers can explore different ideas and iterate quickly. Additionally, it plays a crucial role in the prototyping and testing stages, allowing for precise adjustments and modifications. With the advancement in technology, metalwork 3D CAD can be accessed from anywhere, making it convenient for professionals and enthusiasts alike.

Why Choose Metalwork 3D CAD?

The benefits of metalwork 3D CAD are as vast as they are impressive. By opting for this technology, designers can save time and costs associated with traditional manufacturing processes. Additionally, the ability to visualize designs in 3D enhances communication and collaboration among team members. Metalwork 3D CAD also enables the creation of intricate and complex designs that would be challenging or impossible to achieve through traditional methods. With its precision and accuracy, this tool ensures that every detail is captured flawlessly.

How Does Metalwork 3D CAD Work?

Metalwork 3D CAD operates on the principle of creating a virtual representation of a physical object. Using specialized software, designers develop a digital model, specifying dimensions, shapes, and other crucial details. This model is then converted into a set of instructions that guide the metalwork 3D printer to construct the desired object layer by layer. The printer utilizes various metal fabrication techniques, such as laser sintering or powder bed fusion, to bring the design to life. The result is a stunning, precise metalwork piece ready for further processing or immediate use.

FAQs about Metalwork 3D CAD

Q: What types of metal can be used in metalwork 3D CAD?

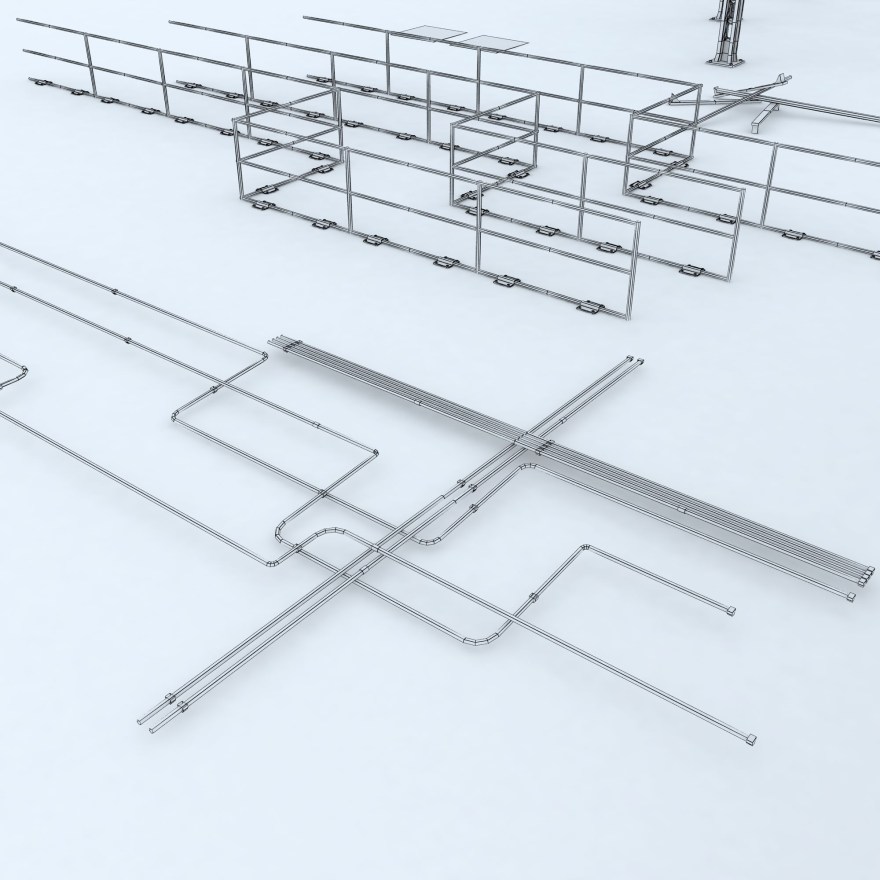

Image Source: turbosquid.com

A: Metalwork 3D CAD is compatible with a wide range of metals, including stainless steel, aluminum, titanium, and even precious metals like gold and silver. The choice of metal depends on the specific requirements of the design and the desired end product.

Q: What is the maximum size that can be achieved with metalwork 3D CAD?

A: The size of the metalwork pieces that can be created using this technology varies depending on the capabilities of the 3D printer. Some printers can accommodate larger objects, while others are more suitable for smaller, intricate designs. It’s essential to consider the printer’s specifications and limitations when determining the size of the desired metalwork.

Q: Is metalwork 3D CAD suitable for high-temperature applications?

A: Absolutely! One of the remarkable qualities of metalwork 3D CAD is its ability to produce metalwork with excellent heat resistance. This makes it ideal for applications that involve high temperatures, such as aerospace components, automotive parts, and industrial machinery.

Q: How much experience is required to use metalwork 3D CAD?

A: Metalwork 3D CAD software varies in complexity, with some platforms offering user-friendly interfaces suitable for beginners. However, mastering the intricacies of metalwork 3D CAD may require some level of training or experience. It’s advisable to invest time in learning the software and understanding the principles of metalwork design to fully leverage its potential.

Pros and Cons of Metalwork 3D CAD

Pros:

Unlimited design possibilities

Enhanced precision and accuracy

Cost and time savings compared to traditional manufacturing methods

Reduced material waste

Improved collaboration and communication among team members

Cons:

High initial investment in equipment and software

Steep learning curve for beginners

Limitations in size and complexity depending on the 3D printer

Potential for technical issues and errors during the printing process

Conclusion: Unlocking Creativity with Metalwork 3D CAD

My experience with metalwork 3D CAD has been nothing short of awe-inspiring. The ability to bring intricate designs to life and witness the transformation from a virtual model to a tangible metalwork piece is truly magical. The advantages of metalwork 3D CAD, such as cost and time savings, improved precision, and limitless design possibilities, make it a must-have tool for anyone involved in metalwork. While there are some challenges and considerations to keep in mind, the rewards far outweigh the drawbacks. I wholeheartedly recommend exploring metalwork 3D CAD and embracing the future of metalwork design and manufacturing.

This post topic: Metalworking