The Ultimate Metal Work Equipment List: Get Your Tools Ready To Transform Metal!

Metal Work Equipment List: A Comprehensive Guide for Every Metalworker

Introduction:

Greetings, fellow metalwork enthusiasts! Today, I want to delve into the fascinating world of metal work equipment list. As a passionate metalworker myself, I understand the importance of having the right tools and equipment to create stunning metal masterpieces. In this comprehensive guide, I will walk you through everything you need to know about metal work equipment list, including its types, sizes, materials, specifications, requirements, and much more. So, let’s dive in and discover the wonders of the metal work equipment list together!

2 Picture Gallery: The Ultimate Metal Work Equipment List: Get Your Tools Ready To Transform Metal!

![Picture of: List of Workshop Tools & Their Uses [Names & PDF]](https://emetal.info/wp-content/uploads/2023/09/list-of-workshop-tools-amp-their-uses-names-amp-pdf.jpg)

What is Metal Work Equipment List?

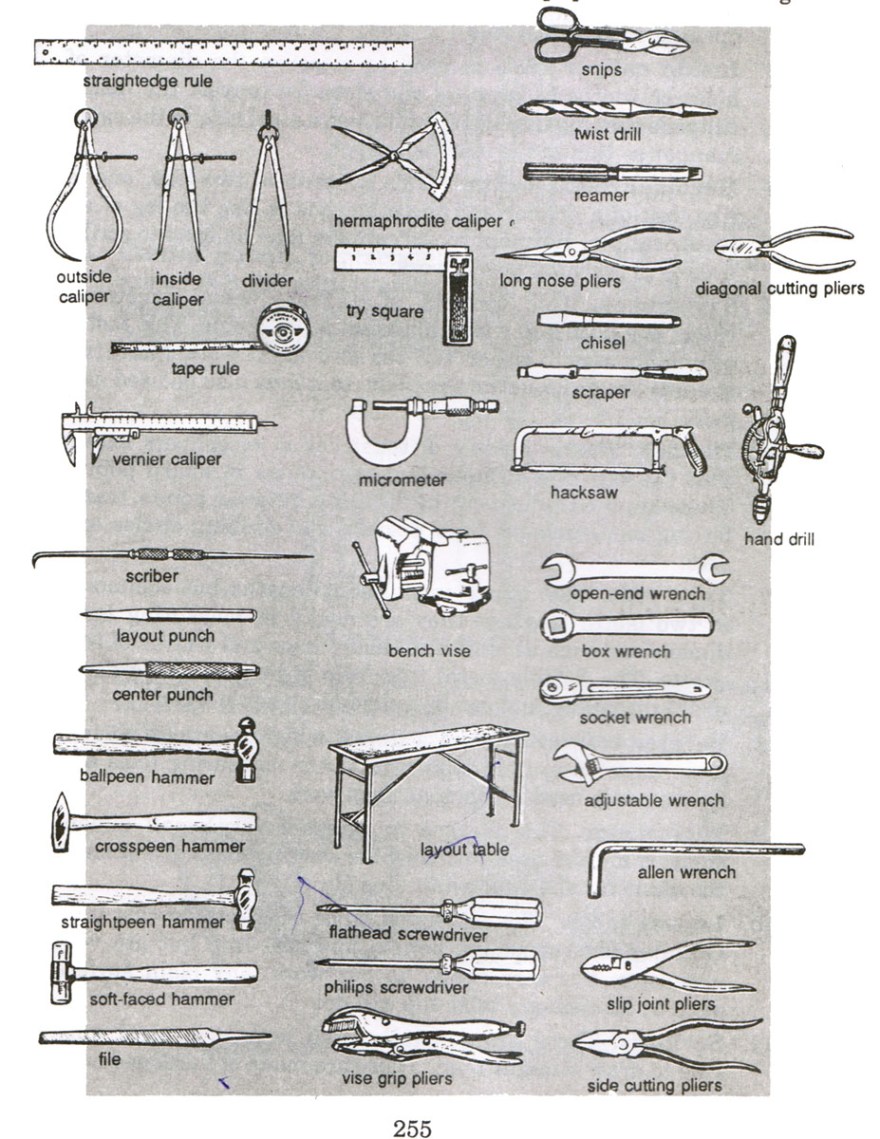

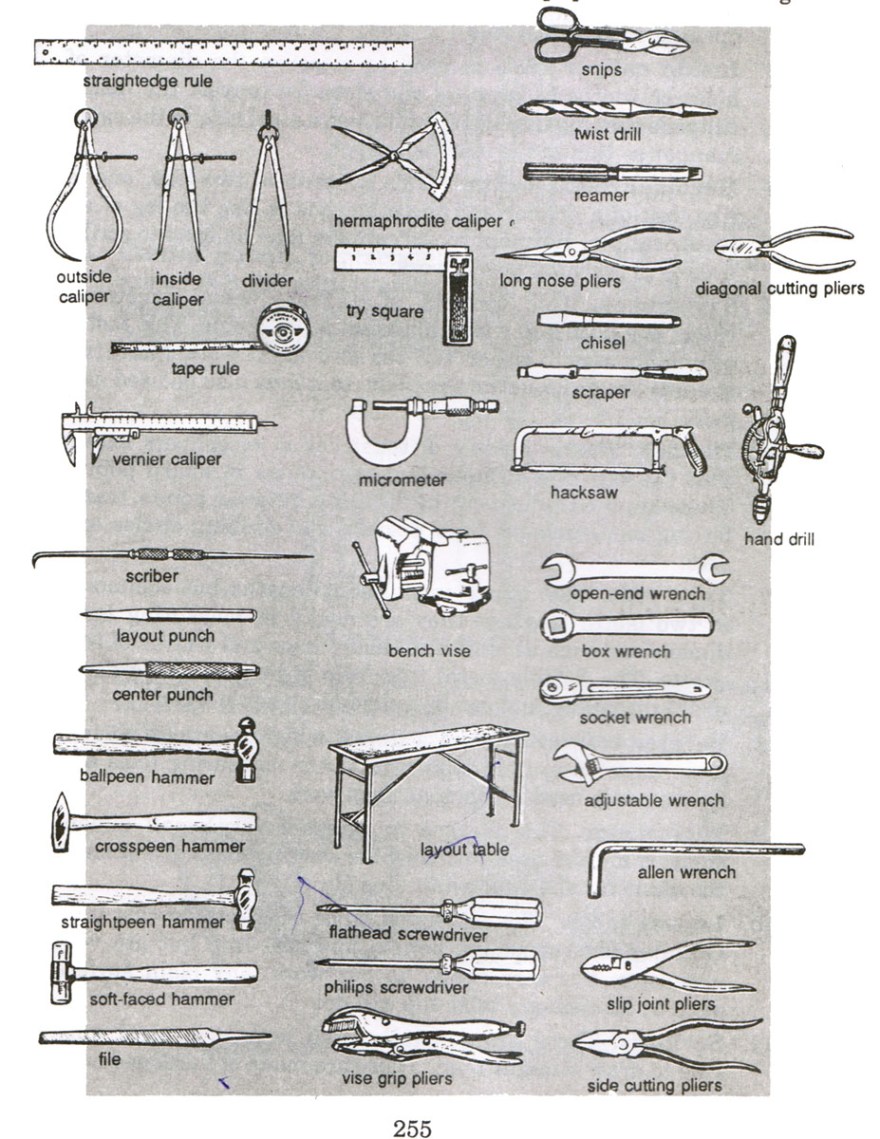

Metal work equipment list refers to a curated collection of tools and machinery required for various metalworking processes. Whether you are a hobbyist or a professional metalworker, having the right equipment is crucial for achieving precise and high-quality results. From cutting and shaping to welding and polishing, metal work equipment list covers a wide range of tools that aid in the fabrication process.

Who Can Benefit from Metal Work Equipment List?

![List of Workshop Tools & Their Uses [Names & PDF] List of Workshop Tools & Their Uses [Names & PDF]](https://emetal.info/wp-content/uploads/2023/09/list-of-workshop-tools-amp-their-uses-names-amp-pdf.jpg)

Image Source: theengineerspost.com

Metal work equipment list caters to a diverse range of individuals and industries. Artisans, sculptors, blacksmiths, and welders are just a few examples of those who heavily rely on these tools. Additionally, industries such as automotive, aerospace, construction, and manufacturing also require metal work equipment list to carry out their operations effectively.

When and Where to Use Metal Work Equipment List?

Metal work equipment list finds its utility in various situations and locations. Whether you are working in a professional workshop, a garage, or even at home, these tools are indispensable for any metalworking project. They can be used to craft intricate jewelry, fabricate automotive parts, create custom furniture, or construct large-scale structures. The versatility of metal work equipment list allows for limitless possibilities in both personal and professional settings.

Why Is Having Metal Work Equipment List Essential?

Investing in a comprehensive metal work equipment list is essential for several reasons. Firstly, it ensures efficiency and accuracy in your metalworking projects. With the right tools at your disposal, you can achieve precise cuts, welds, and finishes, resulting in high-quality craftsmanship. Additionally, having a well-equipped workshop not only enhances productivity but also opens doors to a wider range of creative possibilities. Lastly, professional-grade metal work equipment list enhances safety, reducing the risk of accidents and injuries during the fabrication process.

How to Choose the Right Metal Work Equipment List?

Image Source: blogspot.com

Choosing the right metal work equipment list can be a daunting task, considering the plethora of options available in the market. However, by considering a few key factors, you can make an informed decision. Firstly, assess your specific metalworking needs and requirements. This will help you prioritize the tools you need the most. Secondly, consider the quality and durability of the equipment. Investing in high-quality tools might be more expensive initially, but it will save you money in the long run due to their longevity. Lastly, read reviews and seek recommendations from fellow metalworkers to gain insights into the performance and reliability of different brands and models.

FAQ about Metal Work Equipment List

Q1: How many types of metal work equipment are there?

There is a wide range of metal work equipment available, each serving a specific purpose. Some common types include cutting tools (such as saws and plasma cutters), shaping tools (such as hammers and presses), welding equipment (such as welders and soldering irons), and finishing tools (such as grinders and polishers).

Q2: What are the common materials used in metal work equipment?

Metal work equipment is primarily made of sturdy materials such as steel, aluminum, and cast iron. These materials provide durability and strength, ensuring that the tools can withstand the demands of metalworking processes.

Q3: Are there any specific safety requirements for using metal work equipment?

Yes, safety should always be a top priority when working with metal work equipment. Wearing appropriate protective gear, such as gloves, goggles, and aprons, is essential to prevent accidents and injuries. Additionally, proper ventilation and workspace organization are crucial for creating a safe working environment.

Comparison of Different Metal Work Equipment List

Now, let’s compare some popular metal work equipment list options to help you make an informed decision:

1. Cutting Tools:

– Circular Saw: Ideal for making straight cuts in metal sheets.

– Plasma Cutter: Provides precise and clean cuts through various metals with ease.

– Bandsaw: Perfect for curved cuts and irregular shapes.

2. Shaping Tools:

– Ball Peen Hammer: Used for shaping and bending metal.

– English Wheel: Ideal for creating smooth curves and contours in metal sheets.

– Hydraulic Press: Offers immense force for shaping and forming metal components.

3. Welding Equipment:

– MIG Welder: Versatile and user-friendly, suitable for both beginners and professionals.

– TIG Welder: Allows for precise and high-quality welds, perfect for intricate projects.

– Spot Welder: Ideal for joining thin metal sheets together quickly and efficiently.

4. Finishing Tools:

– Angle Grinder: Used for grinding, sanding, and polishing metal surfaces.

– Bench Grinder: Provides precise sharpening and shaping of metal tools.

– Belt Sander: Perfect for smoothing and refinishing metal surfaces.

The Pros and Cons of Metal Work Equipment List

Pros:

– Enables precise and high-quality metalwork.

– Enhances productivity and creative possibilities.

– Improves safety during the fabrication process.

– Suitable for a wide range of metalworking projects.

Cons:

– Initial investment can be expensive.

– Requires proper maintenance for longevity.

– Some tools may have a steep learning curve for beginners.

Conclusion: Metal Work Equipment List – Unleash Your Metalworking Potential

After exploring the vast world of metal work equipment list, it’s evident how crucial it is for any metalworker, regardless of their skill level or project scope. With the right tools at your disposal, you can transform raw metal into awe-inspiring creations. So, invest wisely, prioritize safety, and let your imagination run wild as you embark on your metalworking journey. Remember, the key to success lies in the quality and versatility of your metal work equipment list. Happy metalworking!

This post topic: Metalworking