Revolutionizing The Metalworking Machinery Manufacturing Industry: Unleashing The Power Of Innovation

The Metalworking Machinery Manufacturing Industry: A World of Precision and Innovation

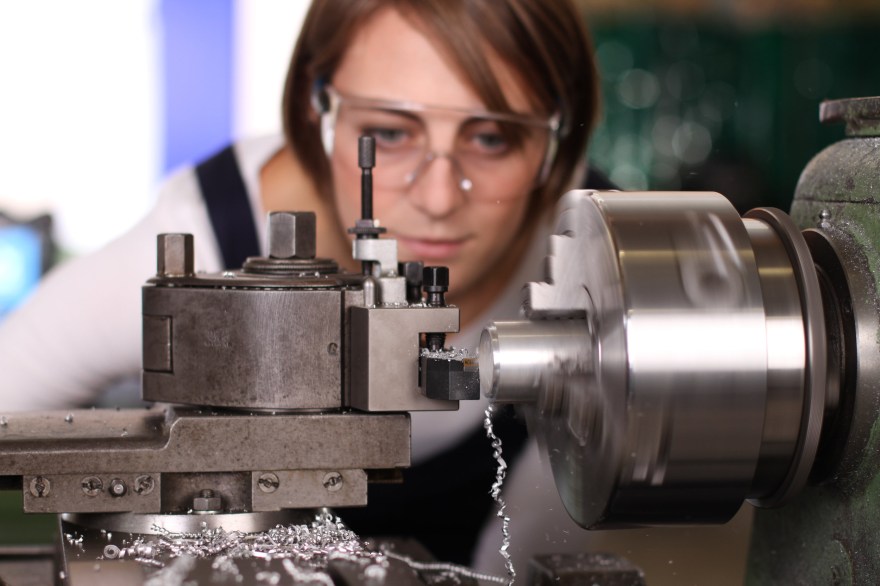

Welcome to the fascinating world of metalworking machinery manufacturing industry, where precision meets innovation to shape the future of manufacturing. In this article, I will take you on a journey through the intricacies of this industry, shedding light on its what, who, when, where, why, and how. Whether you are a curious enthusiast, a professional in the field, or simply intrigued by the wonders of modern machinery, this article will provide you with a comprehensive overview.

What is the Metalworking Machinery Manufacturing Industry?

The metalworking machinery manufacturing industry encompasses the production of a wide range of machines and equipment used in metalworking processes. These machines are essential in various industries, such as automotive, aerospace, construction, and energy, enabling the creation of complex metal parts with unparalleled precision and efficiency.

2 Picture Gallery: Revolutionizing The Metalworking Machinery Manufacturing Industry: Unleashing The Power Of Innovation

Who are the Key Players in the Industry?

The industry is dominated by several key players, both established giants and innovative startups. Companies such as Haas Automation, Mazak, and Trumpf have long been leaders in the field, continuously pushing the boundaries of technology and setting new standards. These companies employ highly skilled engineers, technicians, and designers who work tirelessly to develop cutting-edge solutions.

When and Where did it Begin?

Image Source: isu.pub

The history of the metalworking machinery manufacturing industry can be traced back to the Industrial Revolution, when the demand for advanced machinery grew exponentially. The invention of the steam engine and the advent of mass production techniques paved the way for the development of metalworking machinery. Today, the industry is thriving worldwide, with manufacturing hubs in countries like Japan, Germany, China, and the United States.

Why is the Industry Essential?

The metalworking machinery manufacturing industry plays a crucial role in driving innovation and progress in various sectors. Without these machines, the creation of intricate metal components would be labor-intensive, time-consuming, and prone to errors. From CNC machines and laser cutters to press brakes and milling machines, these tools empower manufacturers to produce high-quality products with remarkable efficiency.

How Does the Industry Work?

The metalworking machinery manufacturing industry operates through a complex process involving research and development, design, production, and distribution. Engineers and designers collaborate to conceptualize new machines, taking into account factors such as precision, speed, durability, and affordability. Manufacturers then leverage advanced technologies, such as computer-aided design and simulation, to turn these concepts into reality.

Frequently Asked Questions (FAQ)

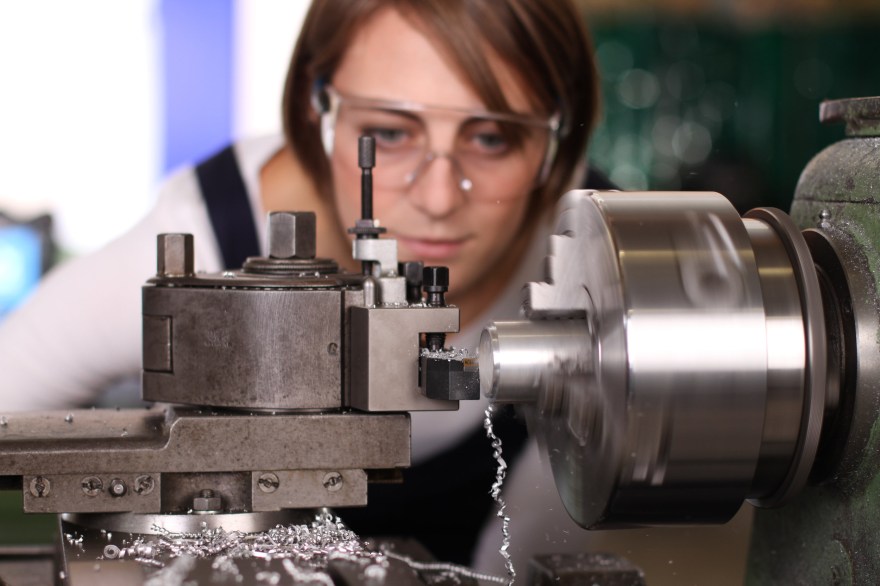

What types of machines are included in the metalworking machinery manufacturing industry?

Image Source: squarespace-cdn.com

The industry encompasses a wide range of machines, including CNC machines, lathes, milling machines, laser cutters, press brakes, and more. Each machine serves a specific purpose in metalworking processes, contributing to the overall production chain.

What materials are commonly used in metalworking machinery manufacturing?

The machines in this industry are typically built using high-strength materials such as cast iron, steel, and aluminum alloys. These materials offer excellent rigidity, stability, and reliability, ensuring optimal performance and longevity.

What are the key specifications to consider when purchasing metalworking machinery?

When purchasing metalworking machinery, factors such as cutting capacity, spindle speed, accuracy, repeatability, and tooling options should be taken into account. It is essential to align the machine’s specifications with the specific requirements of your manufacturing processes.

What are some tips and tricks for maximizing the efficiency of metalworking machinery?

Regular maintenance, proper tool selection, operator training, and adherence to safety protocols are vital for optimizing the efficiency of metalworking machinery. Additionally, staying informed about the latest technological advancements in the industry can help you leverage new features and capabilities to streamline your operations.

What are the benefits and disadvantages of using metalworking machinery?

The benefits of using metalworking machinery are numerous. These machines enhance productivity, improve product quality, increase flexibility, and reduce labor costs. However, they require a significant initial investment and may necessitate specialized training for operators.

How much do metalworking machinery cost?

The cost of metalworking machinery varies significantly depending on factors such as machine type, size, brand, and features. CNC machines, for example, can range from a few thousand dollars for entry-level models to several hundred thousand dollars for high-end industrial-grade machines.

Are there any discounts or promotions available in the industry?

Many manufacturers offer discounts and promotions throughout the year, especially during trade shows and industry events. It is advisable to stay updated with the latest news and announcements from machinery manufacturers to take advantage of these opportunities.

Conclusion

The metalworking machinery manufacturing industry is a fascinating world of precision and innovation that continues to shape the future of manufacturing. From small workshops to large-scale production facilities, these machines enable manufacturers to create intricate metal components with unparalleled accuracy and efficiency. Whether you are a professional in the field or simply interested in the wonders of modern machinery, exploring this industry is sure to leave you in awe of the remarkable achievements and advancements it offers.

Experience the power of metalworking machinery, and witness firsthand how it revolutionizes the way we manufacture products. With a vast array of machines, materials, and technologies at your disposal, the possibilities are endless. With the right equipment and expertise, you can turn your wildest ideas into reality while pushing the boundaries of what is possible in the realm of metalworking. Embrace the spirit of innovation and join the journey of the metalworking machinery manufacturing industry.

This post topic: Metalworking