Revolutionize Metalworking With The Ultimate 3D Printer: Metalworking 3D Printer!

The Revolutionary World of Metalworking 3D Printers

As a self-proclaimed enthusiast and reviewer of innovative products, I have recently delved into the mesmerizing realm of metalworking 3D printers. These cutting-edge machines have completely transformed the way we approach manufacturing, enabling us to create intricate metal designs with precision and efficiency. With a passion for exploring new technologies and a thirst for knowledge, I embarked on a journey to uncover the wonders and capabilities of metalworking 3D printers.

What is a Metalworking 3D Printer?

A metalworking 3D printer, also known as a metal additive manufacturing machine, is a device that uses metal powder or wire as its raw material and employs a layer-by-layer approach to construct three-dimensional objects. Unlike traditional manufacturing methods that involve subtractive processes, such as cutting or milling, metalworking 3D printers add material to create complex shapes and structures. This revolutionary technology has paved the way for unprecedented design possibilities and has significantly reduced production time and costs.

3 Picture Gallery: Revolutionize Metalworking With The Ultimate 3D Printer: Metalworking 3D Printer!

Who Can Benefit from Metalworking 3D Printers?

Metalworking 3D printers have a broad range of applications and can benefit various industries. From automotive and aerospace to healthcare and jewelry, these printers offer immense potential for customization, rapid prototyping, and cost-effective production. Engineers, designers, and manufacturers can now bring their ideas to life with unparalleled precision and intricacy, making metalworking 3D printers a game-changer for the manufacturing industry.

When and Where Did Metalworking 3D Printers Originate?

Image Source: ytimg.com

The concept of 3D printing has been around since the 1980s, but it wasn’t until the early 2000s that metalworking 3D printers started gaining traction. The technology has since evolved rapidly, with advancements in materials, software, and hardware. Today, metalworking 3D printers can be found in research facilities, universities, and industrial settings worldwide.

Why Choose Metalworking 3D Printers?

Metalworking 3D printers offer a multitude of advantages over traditional manufacturing methods. Firstly, they allow for the creation of complex designs that would be impossible to achieve through conventional means. Additionally, these printers offer faster production times, reduced material waste, and the ability to create lightweight yet strong structures. The cost-effectiveness and flexibility of metalworking 3D printers make them an attractive choice for businesses looking to streamline their production processes and stay ahead of the competition.

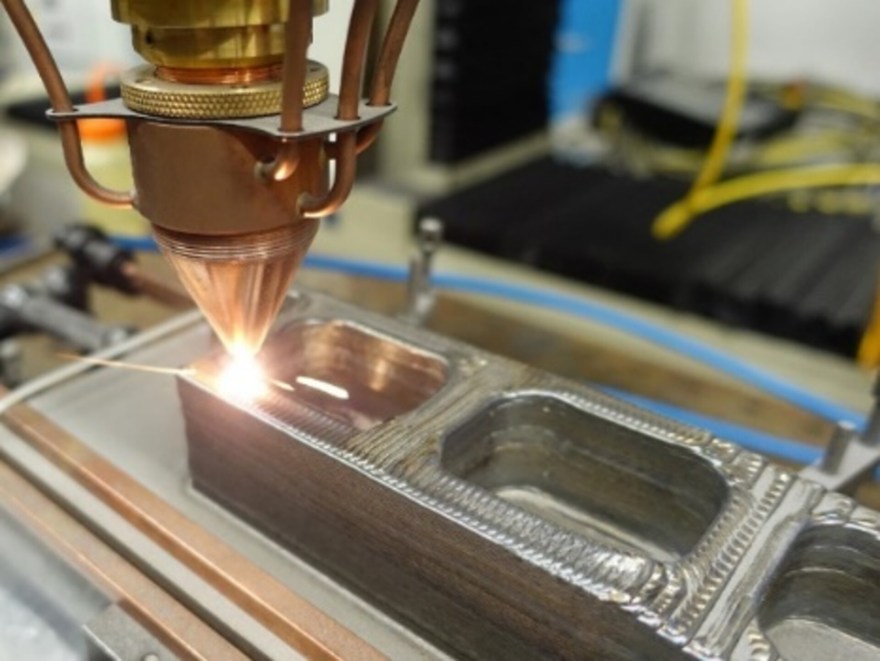

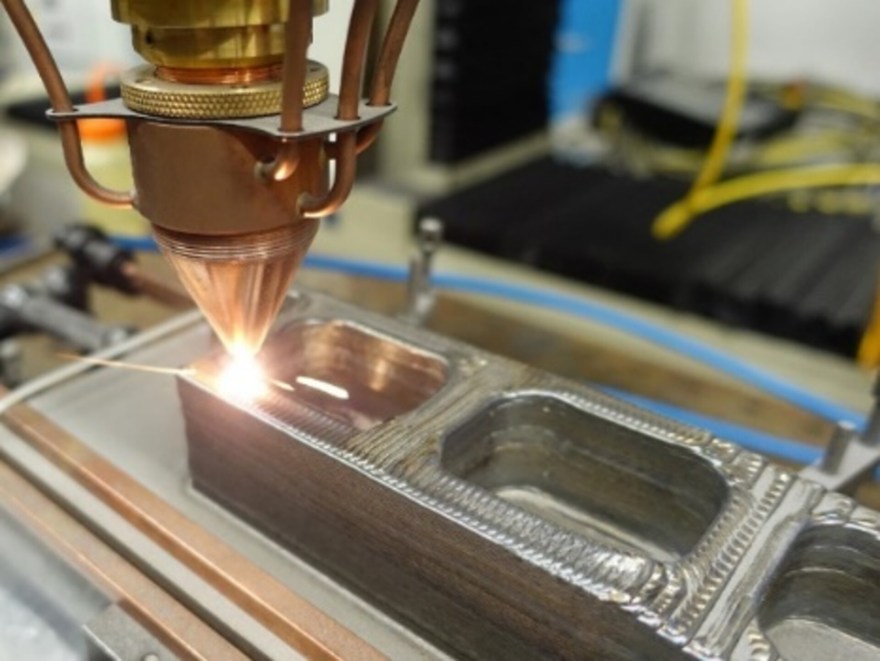

How Do Metalworking 3D Printers Work?

Metalworking 3D printers utilize a process called selective laser melting (SLM) or electron beam melting (EBM) to transform metal powder or wire into solid objects. SLM involves using a high-powered laser to selectively melt the metal powder, fusing it together layer by layer according to a 3D computer-aided design (CAD) model. Similarly, EBM employs an electron beam to melt the metal powder, ensuring high accuracy and precision. Both methods result in objects with excellent mechanical properties, making them suitable for a wide range of applications.

Frequently Asked Questions about Metalworking 3D Printers

What types of materials can be used in metalworking 3D printers?

Image Source: esa.int

Metalworking 3D printers are compatible with various metals, including titanium, stainless steel, aluminum, and nickel alloys. The choice of material depends on the specific requirements of the application and the desired mechanical properties of the final product.

What size objects can metalworking 3D printers produce?

Metalworking 3D printers come in various sizes, ranging from small desktop machines suitable for jewelry production to large industrial printers capable of manufacturing large-scale components for aerospace applications. The size of the printer determines the maximum dimensions of the objects it can produce.

What are the specifications and requirements for operating a metalworking 3D printer?

Operating a metalworking 3D printer requires a dedicated workspace with proper ventilation and safety measures in place. The printer must be connected to a power source and a computer with compatible software to control the printing process. The specifications and requirements vary depending on the specific model and manufacturer.

What are some tips and tricks for optimizing the performance of a metalworking 3D printer?

Image Source: voestalpine.com

To optimize the performance of a metalworking 3D printer, it is crucial to ensure proper calibration, cleanliness, and maintenance of the machine. Regularly inspecting and cleaning the print bed, nozzle, and other components, as well as following manufacturer guidelines, can significantly improve the quality and reliability of the printed objects.

What are the benefits and disadvantages of using metalworking 3D printers?

The benefits of using metalworking 3D printers include increased design freedom, reduced production time, cost-effectiveness, and the ability to create complex and lightweight structures. However, metalworking 3D printers can be expensive to purchase and operate, require specialized knowledge and training, and have limitations in terms of size and resolution.

How much do metalworking 3D printers cost?

The cost of metalworking 3D printers varies depending on the size, specifications, and capabilities of the machine. Entry-level desktop printers can range from a few thousand dollars, while industrial-grade printers can cost several hundred thousand dollars. It is essential to consider the specific requirements and budget constraints before investing in a metalworking 3D printer.

What is the overall verdict on metalworking 3D printers?

Having explored the world of metalworking 3D printers, I can confidently say that they are a revolutionary technology with immense potential. The ability to create intricate metal designs with precision and efficiency opens up endless possibilities for various industries. While there are some challenges and limitations associated with metalworking 3D printers, the benefits far outweigh them. I highly recommend considering these printers for anyone in need of advanced manufacturing capabilities.

Experience the Future of Manufacturing with Metalworking 3D Printers

My experience with metalworking 3D printers has been nothing short of awe-inspiring. Witnessing these machines transform raw materials into intricate metallic structures has given me a newfound appreciation for the power of technology and innovation. The future of manufacturing lies in the hands of metalworking 3D printers, and I am excited to see how they continue to revolutionize various industries in the years to come.

This post topic: Metalworking